A proprietary Statistical Process Control system for real-time monitoring and optimization.

Science.

Innovation.

Wellness.

A VISION FOR

A BRIGHTER, HEALTHIER FUTURE

At IPAR, innovation is more than just products; it represents a movement toward sustainable wellness. By integrating the latest advancements in bioscience, nutrition, and holistic health, we develop solutions that inspire individuals and strengthen communities across generations.

Science-backed Formulation, Engineered For Excellence

At every stage of research, development, and manufacturing, IPAR prioritizes scientific precision, safety, and efficacy. Each product is backed by rigorous testing and quality assurance protocols to ensure consistency and reliability.

ISPC

Methods

Six Sigma

Quality

Reducing defects and variations to enhance manufacturing consistency.

cGMP & HACCP Compliance

Ensuring global safety and quality standards are met or exceeded.

Purity & Identity Verification

Multi-stage testing to confirm authenticity, potency, and safety.

The ISPC Approach (Inspired by the DMAIC framework)

Define

Establish key parameters and customer expectations.

Measure

Track critical manufacturing metrics.

Analyze

Identify root causes of defects.

Improve

Enhance efficiency and eliminate errors.

Control

Maintain process reliability over time.

ISPC Methods

ISPC Methods

ISPC Methods

PRECISION-DRIVEN

QUALITY CONTROL

At IPAR, ISPC Methods (IPAR Statistical Process Control Methods) ensure quality, efficacy, and safety at every stage of development and manufacturing.

Exprience the diffirence

Six Sigma

Six Sigma Precision for Manufacturing Excellence IPAR’s ISPC Methods incorporate Six Sigma quality control principles, focusing on continuous process evolution to: Eliminate defects and variations that impact product reliability. Solve manufacturing inefficiencies before they affect product quality. Enhance consistency and precision through proactive monitoring and control.

cGMP by Intertek

Certified by Intertek, cGMP (Current Good Manufacturing Practices) ensures that manufacturing processes are consistently controlled and meet strict regulatory quality standards. It covers facility hygiene, ingredient traceability, production protocols, and testing procedures, ensuring product integrity and compliance.

HACCP

Preventing Contamination at Every Stage HACCP (Hazard Analysis and Critical Control Points) is a globally recognized preventive system designed to identify, evaluate, and control potential hazards in the production process. By following HACCP principles, IPAR ensures that all products are free from contamination risks and meet strict safety regulations from sourcing to final packaging.

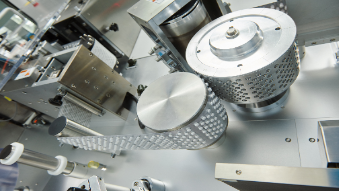

Advanced Manufacturing & Quality Control

Controls

Automated temperature, humidity, and air-shading systems protect raw materials and products, preserving quality, potency, and stability.

& Production

IPAR utilizes high-speed tablet presses, Auto capsule machines, and packaging lines to ensure precision and efficiency. defect detection and scanning further enhance product quality.

Quality Control

Comprehensive QA and QC protocols based on HACCP and cGMP standards ensure safety, consistency, and efficacy across all product categories

Contamination Control

IPAR utilizes high-speed tablet presses, Auto capsule machines, and packaging lines to ensure precision and efficiency. defect detection and scanning further enhance product quality.

Production Excellence

Strictly controlled mixing and drying processes ensure uniform ingredient distribution, stability, and bioavailability. Advanced drying technology preserves potency for optimal texture, dissolution, and absorption.

.png)